One of the significant outcomes of the global pandemic is that organisations are reviewing their business processes, in particular the efficiency and resilience of their supply chain.

Prior to 2020 we became accustomed to being part of a connected world, sourcing product and materials from all corners of the globe with ease. But, with travel and supply routes disrupted by an unexpected and swift closing of international borders, companies have been forced to rethink their sourcing options and look for more secure ways to ensure business continuity through the supply chain.

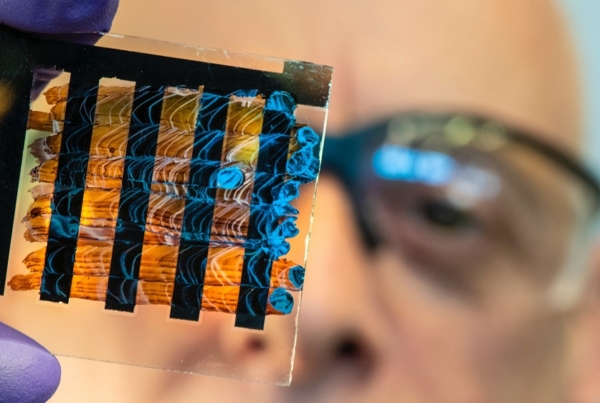

One way has been to look closer to home and support a more local market. Meat producers all along Australia’s eastern seaboard have benefitted from the short-turnaround, bespoke production of our locally processed Casguard range of waxed and clear bone guard products since 2014. Protecting bone-in meat products to keep them fresher for longer in transit and on the shelf, our customised products with fast delivery offer convenience and peace of mind.

After moving our production facilities to our new premises in the middle of 2020, we have increased our capacity and are now supplying Casguard to meat processing customers in our APAC neighbour, Singapore. Our proximity to the Asian continent means that, as with our Australian customers, Casguard is quicker, more convenient and hassle free in comparison to importing from America.

And as a bonus we are reducing CO2 emissions with the shorter transport route.

As we look towards the future of production and efficiencies, combined with a consideration of our impact on the planet, sourcing supplies locally first ticks all the boxes.

If you’d like to know more about how Casguard can improve efficiencies in your supply chain by buying locally rather than from America, contact our customer support team.